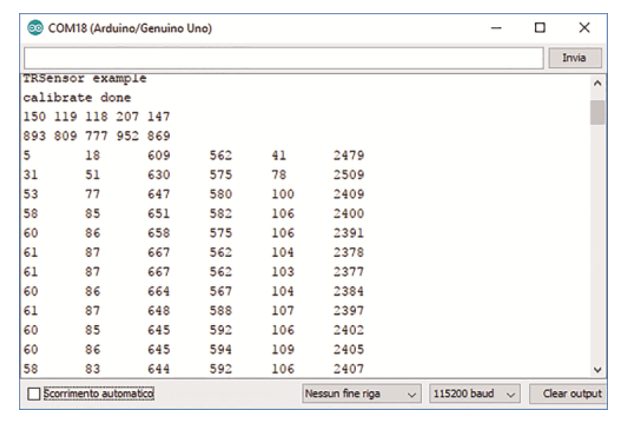

5.3.1. Normalization process

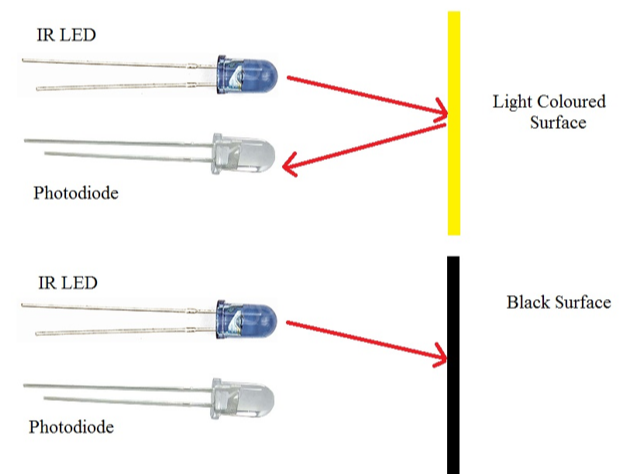

Different sensors may output different results for the same color and distance. Furthermore, environment can affect the range of analog output. For example, if we apply 10AD for sampling, we may get the output range from 0 to 1023 theoretically.

However, what we get actually will be the Min output value higher than 0 and the Max output value lower than 1023. Normalization process is important and necessary for reducing the affecting factors from different sensors and different environments. Normalization process is a kind of linear transformation by transforming the range of Min~Max to the range of 0~1 with the following formulas.

y = (x-Min)/(Max-Min)

In which, x is the original output value from sensor, y is the transformed value, and Max and Min are the maximum output value and the minimum output value, respectively.

y = ((x-Min) * 1000)/(Max-Min)

After transformed, the output value will be in the range of 0~1000, in which 1000 means the sensor is far away from the black line, and 0 means the sensor is above the black line.

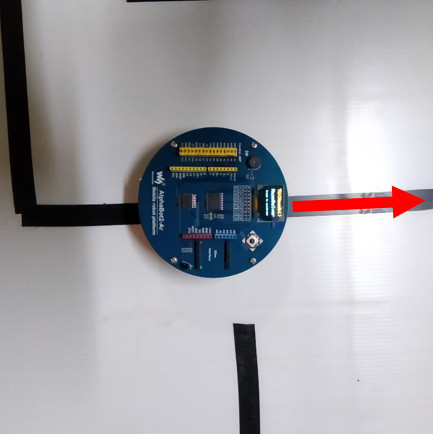

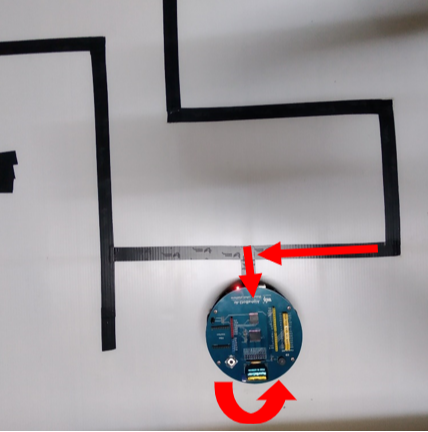

The program will sample the values from the sensors for many times to get the proper value of Min and Max. In order to get the precise Min and Max, the car should be always running in course of sampling.

5.3.2. Weighted average

Using normalization process to deal with five sets of output data, we will get five sets of data about the distances between the sensors and the black line. Then, we should use weighted average to transform these data into a value to determine center line of the route with the following formula:

y = ((0 * value0) + (1000 * value1) + (2000 * value2) + (3000 * value3) + (4000 * value4)) /

(value0 + value1 + value2 + value3 + value4)

In which, 0, 1000, 2000, 3000, 4000 are the weights for the five detectors, respectively, from left to right. And value0~value4 are the data with normalization process.

Now, we can get the data in the range of 0~4000, which can tell you the position of the black line. For example, 2000 means the black line is in the middle of the module, 0 means the black line is on the leftmost side of the module, and 4000 means the black line is on the rightmost side of the module.

For more precise detection, we have some requirements on the height of the module and the width of the black line. The width of the black line should be equal to or less than the distance of two sensors (16mm). The proper height of the module is that when the black line is in the middle of two sensors, both sensors can detect the black line.

5.3.3. PID Control

From Part 2, we can get the position of the black line. You should make sure the black line is always under the car, so that the car can run along the black line. So, the output value after weight average process should be kept at 2000. Here, we employ positional PID control to make the car run smoothly. About the PID algorithm, you can easy get a lot of information via Internet. In here, we only have a brief description on it.

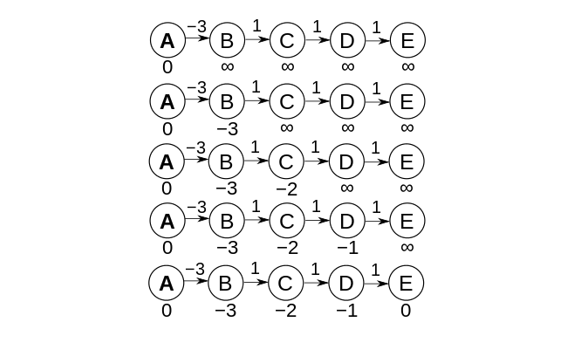

PID control can feedback and regulate the error with three factors, proportional (P), Integral (I), derivative (D). The followings are PID algorithm.

proportional = position - 2000;

derivative = proportional - last proportional;

integral += proportional;

last proportional = proportional;

power error = (proportional * Kp) + (integral * Ki) + (derivative * Kd);

Ideally, the weighted average output is 2000, that is, the black line is kept in the middle. The proportional is the result of current position(Position) minus objective position (2000). It is the position error, of which the positive number means the car is on the right of the black line, and the negative number means the car is on the left of the black line.

Integral is the sum of all the errors. When the absolution value is large, the error accumulation is large too, which means the car go far away from the route. Derivative is the difference of the current proportional and the last proportional, reflecting the response speed of the car. The large derivative value means the fast response speed.

You can adjust the parameters Kp, Ki and Kd to have the better performance. Firstly, we adjust Kp; set the Ki and Kd to 0, and adjust the value of Kp to make the car run along the black line. Then, adjust Ki and Kd; set the parameters to a small value or 0.